Category

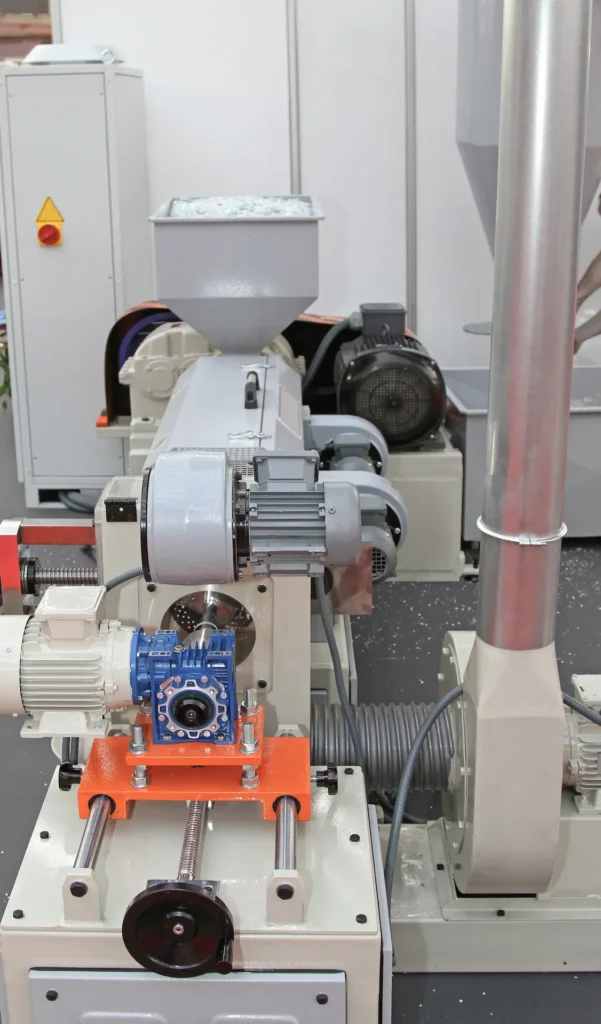

Horizontal RAM Extruder

World-Class Solution in UHMW-PE Technology

Extruder for continuous processing of UHMW-PE or PTFE in a horizontal design. Ideal for profiles and rods.

Keicher Engineering AG from Ulm offers a wide portfolio of state-of-the-art extrusion solutions. Our range includes powerful RAM extruders as well as innovative PTFE extruders that enable precise and uniform processing of demanding plastics. With the modular design of our machines, flexible expansions to fully automated manufacturing systems are possible. Cutting-edge control and regulation technologies ensure the highest quality, efficiency, and a safe production process.

Category

World-Class Solution in UHMW-PE Technology

Extruder for continuous processing of UHMW-PE or PTFE in a horizontal design. Ideal for profiles and rods.

Category

Vertical version of the RAM extruder for thick-walled pipes and space-saving production lines.

Extrusion process with Keicher RAM Extruders The vertical RAM extruder from Keicher Engineering AG enables the continuous production of profiles, especially from PTFE (Polytetrafluoroethylene) and UHMW-PE (Ultra-High Molecular Weight Polyethylene). The raw material is fed into a cylindrical extrusion tube, compressed by a piston, and simultaneously transported through the tube, which is heated to sintering temperature. The individual dosing units sinter together to form a continuous extrudate.

Category

High-precision PTFE extrusion with variable automation options

Paste extrusion of PTFE products like hoses, tapes, or liner pipes. Batch process with preforms and sintering oven.

Category

High-precision PTFE extrusion for medical applications

Special design of the paste extruder for the production of extremely thin-walled PTFE tubing for medical applications.

Category

Complete system for the production of PTFE hoses, liners, wire insulations, and unsintered tapes

Complete system for the production of hoses, tapes, and liner pipes made of PTFE through paste extrusion.

Category

High-quality PTFE coating for conductors through paste extrusion

System for the direct coating of wires with virgin PTFE using paste extrusion. Ideal for high-temperature and high-voltage applications.